Home>Product List

SANWA BRAND

The physical properties of each grade are representative values (catalog values), not guaranteed values.

-

Physical property measurements

Thermal Stability (Heating dimensional change rate) (JIS K 6767): 70℃ environment x 22 hours of recovery ⇒ 23℃ environment x 1 hour of recovery ⇒ This shows the percentage of change in heating dimensions (length and width) from "dimensions before heating. Negative values indicate shrinkage. -

About products

① Regarding the color variations shown below, the color tones differ for each grade depending on the foaming ratio, foam structure, base material, additives, etc.

② In addition to the maximum effective product dimensions shown below, the product can also be sold in widths of 1m x lengths of 1m.

③ The thinnest thickness that can be sliced is different for each grade.

-

About various combustion tests

① All of our products conform to FMVSS 302 (standard on flammability of vehicle interior materials)(Please contact our nearest sales office for the applicable thickness).

② UL94 ・combustion test for railway vehicle materials・ DIN5510(German standard on testing for preventive fire protection in railway vehicles)・14CFR (vertical flame test for aircraft materials)

Certification: Items that have passed the test at an accredited organization.

Equivalent: The product has passed the test conducted by an external testing organization or our company, although an accreditation organization exists.

Compliant: No accreditation body exists, but the product has passed a test conducted by an external testing organization or by our company. - Non-halogenated: Flame retardant products that do not contain halogenated substances (chlorine, bromine, fluorine).

-

Name criteria based on the percentage of sulfur content in our company

Sulfur-free: When no sulfur-containing substances are used, and no sulfur is detected by quantitative analysis of total sulfur content.

Ultralow sulfur: When no sulfur-containing substance is used and total sulfur is undetectable by quantitative analysis, but black carbon is used. Or, when a value of less than 0.02% (200ppm) is detected as a result of measurement.

Low sulfur: When no sulfur powder is used and a value between 0.02% (200ppm) and 0.3% (3000ppm) of total sulfur is detected as a result of quantitative analysis. -

Name criteria for resilience in our company

Ultra-low resilience: The resilience modulus is 10% or less (measured at 23℃).

Low resilience: resilience modulus of 15% or less (measured at 10℃) -

Difference between antibacterial and anti-mold properties

Antibacterial: Objects that are effective in preventing bacteria.

Anti-fungal: Inhibits the growth and development of fungi (mold). -

Surface resistivity: If it is less than 1×108Ω/sq, it is easy to conduct electricity (conductive).

If it is above 1×1010Ω/sq. to 1013Ω/sq. or below, it is difficult to conduct electricity, and electricity is released from the surface of the foam (antistatic property).

Chemical cross-linking

Closed Cell Polyethylene Foam

The world's first lightweight soft polyethylene foam,

developed by us.

The lineup also of features antibacterial

and antifungal foams.

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Feature |

Maximum effective product dimensions |

Color variation |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

% |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS A 1412-2 |

||||||||||||||||||

|

L-600 |

LDPE |

150 |

1.78 |

155 |

430 |

475 |

670 |

3.8 |

1.7 |

-0.6 |

0.063 |

- |

50mm×1m×1m |

Gray・Black |

- |

||||

|

L-800 |

LDPE |

- |

140 |

1.58 |

120 |

380 |

390 |

530 |

6.3 |

3.8 |

-0.4 |

0.064 |

- |

60mm×1m×1m |

Black |

- |

|||

|

L-900 |

LDPE |

110 |

1.48 |

120 |

245 |

275 |

400 |

4.6 |

2.6 |

-0.4 |

0.050 |

- |

60mm×1m×1m |

White・Gray・Black |

✓ |

||||

|

※ |

L-900N |

LDPE |

120 |

1.23 |

180 |

215 |

245 |

375 |

3.6 |

2.0 |

-0.3 |

0.054 |

UL94: HBF Equivalent. Combustion test for railway vehicle materials: Equivalent |

50mm×1m×1m |

(Black) |

- |

|||

|

L-1000 |

LDPE |

100 |

1.24 |

75 |

175 |

200 |

320 |

5.5 |

2.6 |

-1.1 |

0.045 |

- |

60mm×1.1m×1.1m |

White・Gray (Black) |

- |

||||

|

L-1001NN |

LDPE |

105 |

1.39 |

80 |

215 |

245 |

385 |

5.5 |

2.8 |

-0.5 |

0.045 |

UL94: HF-1 Equivalent. 14CFR(For aircraft): Compliant. Halogen-free type |

60mm×1m×1m |

Black |

茶 |

||||

|

L-1002 |

LDPE |

110 |

1.45 |

115 |

235 |

270 |

405 |

3.6 |

1.8 |

-1.0 |

0.047 |

- |

60mm×1m×1m |

Blue (Black) |

- |

||||

|

L-1100 |

LDPE |

90 |

0.98 |

100 |

105 |

130 |

200 |

8.8 |

3.2 |

-0.5 |

0.047 |

- |

60mm×1m×1m |

Gray |

- |

||||

|

L-1400 |

LDPE |

65 |

0.96 |

100 |

115 |

140 |

220 |

4.5 |

2.0 |

-0.4 |

0.043 |

- |

90mm×1m×1m 60mm×1m×2m |

White・Gray・Black・Blue・Red・Yellow・Green |

✓ |

||||

|

L-1500 |

LDPE |

65 |

0.81 |

210 |

110 |

130 |

210 |

4.7 |

1.5 |

-1.0 |

0.042 |

- |

White:85mm×1m×2m non-white:90mm×1m×2m |

White・Gray・Black (Blue) |

✓ |

||||

|

L-1500H |

LDPE |

60 |

0.82 |

175 |

170 |

190 |

280 |

5.6 |

2.1 |

-0.6 |

0.043 |

High Strengh. High heat resistance. Gray (marble pattern)・Black (marble pattern) |

100mm×1m×2m |

White・Gray・Black |

- |

||||

|

L-1501FR(under development) |

LDPE |

- |

- |

85 |

0.40 |

90 |

75 |

100 |

175 |

9.5 |

4.0 |

-1.0 |

- |

UL94: HF-1 Equivalent. 14CFR(For aircraft): Compliant. Halogen-free type |

60mm×1m×1m |

- |

|||

|

L-2000 |

LDPE |

45 |

0.45 |

220 |

75 |

90 |

160 |

4.8 |

1.6 |

-1.2 |

0.037 |

- |

100mm×1m×2m |

White・Gray・Black・Blue (Red・Yellow・Green) |

- |

||||

|

L-2500 |

LDPE |

30 |

0.43 |

175 |

30 |

50 |

115 |

10.1 |

3.6 |

-2.1 |

0.033 |

- |

100mm×1m×2m |

White・Gray・Black・Blue・Red・Yellow・Green |

- |

||||

|

※ |

L-2500NN |

LDPE |

35 |

0.41 |

170 |

35 |

55 |

115 |

9.5 |

3.3 |

-2.1 |

0.035 |

UL94: HF-1 Certified. 14CFR(For aircraft): Compliant. Combustion test for railway vehicle materials: Certified. DIN 5510: Compliant |

100mm×1m×2m |

(Gray・Black) |

- |

|||

|

L-2501NNN |

LDPE |

35 |

0.30 |

110 |

35 |

50 |

110 |

12.5 |

5.2 |

-1.7 |

0.035 |

UL94: HF-1 Certified. Combustion test for railway vehicle materials: Certified. Halogen-free type |

100mm×1m×2m |

Gray (White・Black) |

- |

||||

|

L-2521NN |

LDPE |

30 |

0.22 |

80 |

30 |

50 |

110 |

11.8 |

6.4 |

-0.6 |

0.035 |

UL94: HF-1 Equivalent. Combustion test for railway vehicle materials: Certified. Antifungal. Halogen-free type |

100mm×1m×2m |

Black |

- |

||||

|

L-4000 |

LDPE |

25 |

0.22 |

170 |

20 |

40 |

95 |

14.0 |

5.8 |

-2.9 |

0.033 |

- |

90mm×1m×2m |

White (Gray) |

- |

||||

|

※ |

L-4000NN |

LDPE |

25 |

0.15 |

235 |

25 |

40 |

90 |

16.4 |

10.6 |

-3.0 |

0.031 |

UL94: HF-1 Equivalent. 14CFR(For aircraft): Compliant. Combustion test for railway vehicle materials: Certified. Excellent heat insulation |

90mm×1m×2m |

(Gray) |

- |

|||

|

※ |

SL-3000 |

LDPE |

30 |

0.28 |

130 |

25 |

45 |

105 |

12.6 |

5.2 |

-0.7 |

0.037 |

Long polyethylene foam. Slicing not available. Cutting available upon request |

5mm×1m×100m 10mm×1m×50m 15mm×1m×50m |

(White・Black) |

- |

|||

|

※ |

SL-3000NN |

LDPE |

35 |

0.26 |

115 |

25 |

45 |

105 |

12.4 |

6.0 |

-1.0 |

0.036 |

UL94: HF-1 Certified. Combustion test for railway vehicle materials: Certified. Slicing not available. Cutting available upon request |

10mm×1m×50m |

(Black) |

- |

|||

|

LB-1500 |

Biomass |

65 |

0.67 |

320 |

120 |

140 |

220 |

5.1 |

1.8 |

-0.8 |

0.044 |

BP Mark certification. Biomass Mark Certified. 50% Reduction of CO2 emissions |

100mm×1m×2m |

White・Gray・Black・Blue・Red・Yellow・Green |

- |

||||

|

LB-2500 |

Biomass |

30 |

0.25 |

210 |

30 |

50 |

110 |

10.2 |

3.7 |

-1.6 |

0.033 |

BP Mark certification. Biomass Mark Certified. 50% Reduction of CO2 emissions |

100mm×1m×2m |

White・Gray・Black・Blue・Red・Yellow・Green |

- |

||||

|

LB-2500NN |

Biomass |

35 |

0.35 |

210 |

30 |

50 |

115 |

14.8 |

6.3 |

-1.6 |

0.035 |

BP Mark certification. 30% Reduction of CO2 emissions. UL94: HF-1 Equivalent. Combustion test for railway vehicle materials: Equivalent |

100mm×1m×2m |

Gray |

- |

||||

|

C-600 |

EVA |

160 |

1.52 |

150 |

190 |

235 |

390 |

3.2 |

2.0 |

-1.4 |

0.053 |

- |

60mm×1m×1m |

White |

- |

||||

|

C-700 |

EVA |

- |

130 |

1.21 |

165 |

115 |

145 |

255 |

3.4 |

1.6 |

-1.3 |

0.050 |

- |

40mm×1.1m×1.1m |

Green grass |

||||

|

S-900 |

EVA |

- |

90 |

1.12 |

110 |

65 |

90 |

175 |

6.2 |

2.1 |

-2.2 |

0.045 |

- |

48mm×0.95m×1.9m |

Gray |

- |

|||

|

C-910N |

EVA |

- |

90 |

0.93 |

150 |

45 |

70 |

145 |

5.0 |

1.9 |

-2.2 |

0.047 |

UL94: HBF Equivalent. Combustion test for railway vehicle materials: Equivalent. Antibacteria |

75mm×0.95m×0.95m |

Blue |

Pink |

|||

|

C-1000 |

EVA |

110 |

1.52 |

115 |

150 |

185 |

310 |

3.0 |

1.4 |

-1.4 |

0.049 |

- |

55mm×1m×1m |

Gray (White) |

- |

||||

|

CF-1000 |

EVA |

- |

110 |

0.93 |

110 |

110 |

140 |

245 |

4.3 |

1.6 |

-0.2 |

0.045 |

- |

50mm×0.92m×1.82m |

White・Gray |

- |

|||

|

TC-1000 |

EVA |

90 |

1.29 |

160 |

75 |

105 |

195 |

2.6 |

1.0 |

-2.9 |

0.044 |

- |

50mm×0.87m×1.75m |

Black・Blue |

- |

||||

|

C-1202 |

EVA |

70 |

1.22 |

165 |

60 |

90 |

170 |

5.4 |

1.9 |

-3.2 |

0.044 |

- |

60mm×1m×1m |

Gray・Blue (White・Black) |

- |

||||

|

C-1400 |

EVA |

65 |

0.98 |

200 |

25 |

40 |

95 |

7.8 |

3.2 |

-7.9 |

0.040 |

- |

50mm×1m×2m |

White・Gray |

- |

||||

|

C-3000 |

EVA |

30 |

0.47 |

270 |

15 |

30 |

80 |

8.2 |

3.8 |

-3.4 |

0.033 |

- |

75mm×1m×2m |

White |

- |

||||

|

G-15 |

Special PE |

60 |

1.22 |

245 |

20 |

40 |

100 |

9.5 |

2.1 |

-20.7 |

0.042 |

High gripping. High resilience |

80mm×1m×1m |

Black |

- |

||||

|

T-15#2 |

Special PE |

60 |

1.51 |

220 |

35 |

60 |

125 |

5.9 |

1.6 |

-7.3 |

0.042 |

High gripping. High resilience |

80mm×1m×1m 50mm×1m×2m |

Gray・Black (White) |

- |

||||

|

T-1500 |

Special PE |

65 |

0.70 |

320 |

45 |

65 |

135 |

10.2 |

3.0 |

-2.1 |

0.041 |

High resilience. Sulfur-free |

80mm×1m×2m |

Black |

- |

||||

|

HG-05 |

Special PE |

250 |

2.12 |

335 |

70 |

110 |

260 |

4.7 |

2.3 |

-11.0 |

0.055 |

High resilience |

40mm×0.95m×0.95m |

Green |

- |

||||

|

HG-10 |

Special PE |

180 |

1.40 |

305 |

45 |

75 |

175 |

6.7 |

2.9 |

-4.8 |

0.049 |

High resilience |

50mm×1m×1m |

Orange |

|||||

|

※ |

SSA-06 |

Elastomer |

- |

145 |

0.90 |

295 |

15 |

30 |

90 |

6.6 |

2.5 |

-2.0 |

0.041 |

Ultralow resilience |

40mm×1m×1m |

(Black) |

- |

||

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Feature |

Maximum effective product dimensions |

Color variation |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

% |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS A 1412-2 |

||||||||||||||||||

|

R-06 |

Recycled PE |

- |

140 |

1.50 |

145 |

400 |

450 |

670 |

9.0 |

4.5 |

-0.3 |

0.051 |

Eco mark: Certified |

50mm×1m×1m |

Gray・Black |

- |

|||

|

R-08 |

Recycled PE |

- |

140 |

1.50 |

110 |

370 |

400 |

580 |

7.0 |

4.0 |

-0.4 |

0.051 |

Eco mark: Certified |

60mm×1m×1m |

Gray・Black |

- |

|||

|

R-12 |

Recycled PE |

- |

90 |

1.00 |

90 |

160 |

185 |

280 |

8.3 |

4.6 |

-0.7 |

0.048 |

Eco mark: Certified |

65mm×1m×1m |

Gray・Black |

- |

|||

|

R-15 |

Recycled PE |

- |

60 |

0.50 |

120 |

115 |

130 |

185 |

7.5 |

4.0 |

-0.1 |

0.044 |

Eco mark: Certified |

80mm×1m×1m |

Gray・Black |

- |

|||

|

R-25 |

Recycled PE |

- |

30 |

0.15 |

125 |

30 |

40 |

90 |

9.6 |

4.8 |

-2.6 |

0.034 |

Eco mark: Certified |

80mm×1m×2m |

Gray |

- |

|||

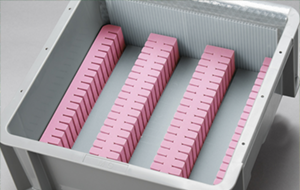

Chemical cross-linking

Conductive Polyethylene Foam

(Closed Cell, Open Cell)

Antistatic Polyethylene Foam

(Closed Cell)

Set to change the future of IT, NEWPELCA products

suppress the damage and malfunctions

in electronic circuit caused by static electricity.

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Feature |

Maximum effective product dimensions |

Color variation |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

% |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS A 1412-2 |

||||||||||||||||||

|

LCX-150T |

PE/EVA |

65 |

0.37 |

40 |

160 |

175 |

265 |

5.4 |

2.6 |

-0.1 |

0.041 |

Surface resistivity: 1×10³Ω/□. Conductive. UL94: HBF Equivalent. Combustion test for railway vehicle materials: Equivalent |

80mm×1m×1m |

Black |

- |

||||

|

LCX-50 |

PE/EVA |

- |

120 |

1.24 |

80 |

275 |

295 |

415 |

6.2 |

3.2 |

-0.1 |

0.062 |

Surface resistivity: 4×10⁶Ω/□. Conductive |

50mm×1m×1m |

Black |

- |

|||

|

LCX-150 |

PE/EVA |

55 |

0.28 |

45 |

130 |

140 |

210 |

7.3 |

2.1 |

-0.2 |

0.038 |

Surface resistivity: 2×10⁷Ω/□. Conductive |

80mm×1m×1m |

Black |

- |

||||

|

LCX-150M |

PE/EVA |

60 |

0.75 |

115 |

135 |

150 |

235 |

4.6 |

2.2 |

-0.3 |

0.038 |

Surface resistivity: 6×10⁶Ω/□. Conductive |

80mm×1m×2m |

Black |

- |

||||

|

LCX-200#1 |

PE/EVA |

50 |

0.30 |

125 |

30 |

50 |

110 |

9.9 |

2.9 |

-1.0 |

0.036 |

Surface resistivity: 2×10⁷Ω/□. Conductive |

80mm×1m×2m |

Black |

- |

||||

|

LCX-200#2 |

PE/EVA |

50 |

0.23 |

50 |

85 |

100 |

165 |

7.6 |

3.3 |

-0.6 |

0.036 |

Surface resistivity: 6×10⁷Ω/□. Conductive |

80mm×1m×2m |

Black |

- |

||||

|

LCX-300 |

PE/EVA |

30 |

0.23 |

40 |

50 |

70 |

130 |

11.4 |

4.7 |

-0.4 |

0.034 |

Surface resistivity: 8×10⁷Ω/□. Conductive |

80mm×1m×2m |

Black |

- |

||||

|

※ |

OX-200#1 |

PE/EVA |

50 |

0.28 |

115 |

4 |

10 |

19 |

1.6 |

1.3 |

-1.4 |

0.040 |

Surface resistivity: 1×10⁷Ω/□. Conductive. Open-cell |

70mm×1m×2m |

(Black) |

- |

|||

|

※ |

SX-100H |

PE/EVA |

- |

90 |

0.65 |

190 |

75 |

100 |

175 |

9.2 |

5.0 |

-0.6 |

0.047 |

Surface resistivity: 3×10⁹Ω/□. Antistatic |

70mm×1m×2m |

(Red) |

- |

||

|

SX-150H |

PE/EVA |

65 |

0.71 |

350 |

115 |

130 |

210 |

6.3 |

2.7 |

-0.9 |

0.042 |

Surface resistivity: 2×10¹²Ω/□. Antistatic |

90mm×1m×2m |

Gray |

- |

||||

|

SX-300H |

PE/EVA |

30 |

0.30 |

200 |

25 |

45 |

105 |

8.1 |

3.4 |

-1.3 |

0.033 |

Surface resistivity: 1×10¹¹Ω/□. Antistatic |

100mm×1m×2m |

Red (Black・Blue) |

- |

||||

|

SXB-150H |

Biomass |

65 |

0.55 |

350 |

120 |

135 |

215 |

3.3 |

1.9 |

-1.4 |

0.042 |

BP Mark certification. 50% Reduction of CO2 emissions. Surface resistivity: 2×10¹²Ω/□. Antistatic |

90mm×1m×2m |

Gray |

- |

||||

|

SXB-300H |

Biomass |

25 |

0.23 |

205 |

25 |

45 |

100 |

11.3 |

4.6 |

-1.4 |

0.033 |

BP Mark certification. 50% Reduction of CO2 emissions. Surface resistivity: 1×10¹¹Ω/□. Antistatic |

100mm×1m×2m |

Red |

- |

||||

Chemical cross-linking

Open Cell Polyethylene Foam

The world's first open cell polyethylene foam,

developed by us.

Now used widely all over the world.

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Feature |

Maximum effective product dimensions |

Color variation |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

% |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS A 1412-2 |

||||||||||||||||||

|

LC-150 |

EVA/PE |

- |

50 |

0.27 |

275 |

9 |

10 |

14 |

3.1 |

1.6 |

-0.5 |

0.047 |

- |

85mm×1m×2m |

White (Black) |

- |

|||

|

※ |

LC-300#2 |

EVA/PE |

- |

30 |

0.13 |

235 |

3 |

4 |

5 |

3.7 |

1.2 |

-0.8 |

0.034 |

- |

85mm×1m×2m |

(Blue) |

✓ |

||

|

LC-300#1 |

EVA/PE |

30 |

0.11 |

210 |

3 |

4 |

5 |

4.0 |

1.5 |

-1.5 |

0.036 |

- |

75mm×1m×2m |

White・Black |

✓ |

||||

|

LC-300#2D |

EVA/PE |

30 |

0.11 |

240 |

3 |

4 |

5 |

4.8 |

2.6 |

-1.0 |

0.040 |

High sound absorption |

85mm×1m×2m |

Black |

- |

||||

|

※ |

LC-300#3 |

EVA/PE |

30 |

0.14 |

185 |

3 |

4 |

5 |

4.3 |

1.8 |

-0.3 |

0.040 |

- |

85mm×1m×2m |

(White・Black・Blue・Red) |

✓ |

|||

|

LR-300#2 |

EVA/PE |

30 |

0.07 |

150 |

2 |

3 |

4 |

4.3 |

1.9 |

-0.6 |

0.040 |

Heat-resistant |

80mm×1m×2m |

Black (White) |

- |

||||

Chemical cross-linking

Open Cell Polyethylene Foam

(fire-retardant type)

This is a foam with fire retardant

that suits every field of industry.

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Feature |

Maximum effective product dimensions |

Color variation |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

% |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS A 1412-2 |

||||||||||||||||||

|

LC-3000#2 |

EVA/PE |

35 |

0.17 |

260 |

5 |

6 |

8 |

3.3 |

1.5 |

-0.8 |

0.040 |

UL94: HF-1 Equivalent. Combustion test for railway vehicle materials: Certified. DIN 5510: Compliant |

85mm×1m×2m |

Black |

- |

||||

|

LC-3000#2NN |

EVA/PE |

35 |

0.11 |

200 |

5 |

6 |

8 |

2.8 |

1.4 |

-1.8 |

0.035 |

UL94: HF-1 Certified. Combustion test for railway vehicle materials: Certified |

85mm×1m×2m |

Black |

- |

||||

|

LC-3001#2 |

EVA/PE |

35 |

0.16 |

245 |

5 |

6 |

8 |

3.8 |

1.8 |

-0.6 |

0.034 |

UL94: HF-1 Certified. Combustion test for railway vehicle materials: Certified. DIN 5510: Compliant. Halogen-free type |

85mm×1m×2m |

Black |

- |

||||

|

LC-3001#2D |

EVA/PE |

35 |

0.11 |

205 |

4 |

5 |

7 |

4.8 |

2.5 |

-0.9 |

0.033 |

UL94: HF-1 Equivalent. High sound absorption. Halogen-free type |

85mm×1m×2m |

Black |

- |

||||

Chemical cross-linking

Closed Cell Rubber Foam

A product that can block water, sound, and even air.

A foam with excellent heat insulation

and repulsion performance.

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Chardness |

Feature |

Maximum effective product dimensions |

Color variation |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

― |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS K 6251 |

ASTM D 1056準用 |

JIS K 7312 |

JIS A 1412-2 |

|||||||||||||||

|

※ |

CR-100NN |

CR |

145 |

0.57 |

225 |

15 |

35 |

90 |

44.9 |

28.9 |

10 |

0.041 |

UL94: HF-1 Equivalent. Combustion test for railway vehicle materials: Certified |

40mm×1m×1m |

(Black) |

- |

|||

|

CR-250NN |

CR |

180 |

0.75 |

170 |

40 |

65 |

145 |

34.7 |

21.8 |

25 |

0.047 |

UL94: HF-1 Certified. Combustion test for railway vehicle materials: Certified. DIN 5510: Compliant |

50mm×1m×1m 30mm×1m×2m |

Black |

- |

||||

|

EP-070 |

EPDM |

100 |

0.30 |

300 |

10 |

25 |

75 |

59.3 |

32.8 |

7 |

0.044 |

Low sulfur |

70mm×1m×2m |

Black |

- |

||||

|

EP-100 |

EPDM |

100 |

0.39 |

280 |

15 |

35 |

95 |

63.9 |

40.9 |

10 |

0.044 |

Ultralow sulfur |

70mm×1m×2m |

Black |

- |

||||

|

※ |

EP-101 |

EPDM |

100 |

0.29 |

420 |

15 |

30 |

90 |

80.0 |

41.6 |

10 |

0.041 |

Ultralow sulfur |

70mm×1m×2m |

(Gray) |

- |

|||

|

※ |

EP-130 |

EPDM |

- |

135 |

0.56 |

200 |

20 |

40 |

110 |

77.5 |

39.8 |

13 |

0.051 |

Low sulfur |

48mm×1m×2m |

(Black) |

- |

||

|

EP-151 |

EPDM |

95 |

0.44 |

290 |

25 |

40 |

110 |

62.7 |

37.6 |

15 |

0.041 |

Sulfur-free |

70mm×1m×2m |

White |

- |

||||

|

EP-200 |

EPDM |

95 |

0.59 |

210 |

35 |

55 |

125 |

69.5 |

35.3 |

20 |

0.045 |

Ultralow sulfur |

70mm×1m×2m |

Black |

- |

||||

|

※ |

EP-200NN |

EPDM |

100 |

0.44 |

230 |

25 |

45 |

110 |

65.2 |

39.0 |

18 |

0.049 |

UL94: HF-1 Certified. Halogen-free type. Ultralow sulfur |

65mm×1m×2m |

(Black) |

- |

|||

|

EP-500 |

EPDM |

140 |

1.60 |

210 |

130 |

170 |

290 |

20.6 |

9.3 |

47 |

0.056 |

Ultralow sulfur |

40mm×1m×1m |

Black |

- |

||||

|

※ |

EVG-200 |

EVA |

230 |

0.69 |

325 |

45 |

70 |

155 |

66.9 |

10.2 |

26 |

0.118 |

UL94: V-0 Equivalent. Combustion test for railway vehicle materials: Equivalent. EN 45545-2: Compliant |

50mm×1m×1m |

Black |

- |

|||

|

※ |

NP-1100NN |

NBR/PVC |

70 |

0.22 |

145 |

5 |

10 |

50 |

40.3 |

26.8 |

2 |

0.038 |

UL94: V-0 Equivalent. Combustion test for railway vehicle materials: Certified. 25mm thickness with skin is available |

25mm×1m×2m 25mm×1m×10m |

(Black) |

- |

|||

Chemical cross-linking

Open Cell Rubber Foam

This product fits snugly into irregular spaces.

A close-contact type stopper that takes advantage

of the characteristics of rubber.

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Feature |

Maximum effective product dimensions |

Color variation |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

% |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS A 1412-2 |

||||||||||||||||||

|

※ |

OP-070 |

EPDM |

195 |

0.25 |

440 |

5 |

7 |

12 |

4.2 |

1.0 |

-0.6 |

0.071 |

High density. High water-sealing |

36mm×0.9m×1.75m |

(Black) |

- |

|||

|

OP-090 |

EPDM |

110 |

0.14 |

250 |

3 |

4 |

6 |

2.1 |

0.7 |

-0.4 |

0.047 |

- |

50mm×1m×2m |

Black |

- |

||||

|

OP-110 |

EPDM |

100 |

0.12 |

270 |

2 |

3 |

5 |

1.5 |

0.8 |

-0.7 |

0.046 |

- |

65mm×1m×2m |

Black |

- |

||||

|

OP-130 |

EPDM |

80 |

0.10 |

205 |

1 |

2 |

3 |

1.5 |

0.7 |

-0.4 |

0.041 |

- |

80mm×1m×2m |

Black |

- |

||||

|

※ |

OP-130N |

EPDM |

75 |

0.08 |

215 |

1 |

2 |

3 |

2.9 |

0.3 |

-0.2 |

0.039 |

UL94: HBF Equivalent. Halogen-free type |

75mm×1m×2m |

(Black) |

- |

|||

|

OP-130NNN |

EPDM |

75 |

0.10 |

385 |

1 |

2 |

3 |

4.2 |

1.0 |

-0.1 |

0.041 |

UL94: HF-1 Certified. Combustion test for railway vehicle materials: Certified. DIN 5510: Compliant |

75mm×1m×2m |

Black |

- |

||||

|

OP-130 OF |

EPDM |

65 |

0.10 |

270 |

1 |

2 |

3 |

2.9 |

0.6 |

-0.1 |

0.038 |

Oil free |

80mm×1m×2m |

Black |

- |

||||

|

OP-131 |

EPDM |

70 |

0.05 |

195 |

1 |

1 |

2 |

3.2 |

0.4 |

-0.1 |

0.038 |

- |

75mm×1m×2m |

White・Gray |

- |

||||

|

OP-180 |

EPDM |

55 |

0.06 |

180 |

1 |

1 |

2 |

4.0 |

1.5 |

-0.8 |

0.035 |

- |

70mm×1m×2m |

Black |

- |

||||

|

※ |

NP-140NN |

NBR/PVC |

65 |

0.15 |

180 |

1 |

2 |

3 |

2.9 |

1.2 |

-0.2 |

0.035 |

UL94: V-0 Equivalent. Combustion test for railway vehicle materials: Certified. 25mm thickness with skin is available. Halogen-free type |

25mm×1m×2m |

(Black) |

- |

|||

Open Cell Melamine Foam

This product is excellent at absorbing sound,

resisting heat, and retarding fire.

It is an ultra-lightweight foam resistant

to severe environments.

View grade list

|

Grade |

Base material |

Physical properties |

SDS |

RoHS2.0 |

Feature |

Maximum effective product dimensions |

Color variation |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

10% |

25% |

50% |

30 minutes later |

24 hours later |

(at 0℃) |

Standard colors(Made to order colors) |

Other colors |

||||||||||||

|

kg/m3 |

MPa |

% |

kPa |

% |

% |

% |

W/m・K |

||||||||||||

|

JIS K 6767 |

JIS A 1412-2 |

||||||||||||||||||

|

M-100 |

Melamine |

9 |

0.16 |

20 |

7 |

11 |

17 |

9.8 |

4.7 |

-0.4 |

0.030 |

UL94: V-0 Equivalent. Combustion test for railway vehicle materials: Certified. 14CFR (For aircraft): Compliant. Heat resistance. High sound absorption. Halogen-free type |

100mm×1.2m×1.25m |

Light Gray |

|||||